MIL-DTL-62069G(AT)

basic control unit housing, the operation of replacing the lamp shall not expose the switch

contact or any other moving internal parts of the control unit to the entry of foreign matter, and

the unit shall maintain the waterproofness requirement after lamp replacement.

3.3.5 Hazard warning switch. The control unit shall have a hazard warning switch in a

location such that accidental operation shall be prevented. The hazard warning switching device

shall disengage when the signal control lever is actuated.

3.4 Electrical.

3.4.1 Voltage rating. Control and flasher units shall be suitable for use in nominal

24 volt direct current (dc) electrical systems (see 4.4.3.2.1).

3.4.2 Current rating. Except as otherwise indicated, current carrying parts shall be able

to withstand a continuous dc current of 10 amperes without damage (see 4.4.3.2.1).

3.4.3 Load impedance. The flasher unit shall be operable with an inductive load of

0.20 millihenries placed in series with the lamp load (see 4.4.3.2.1).

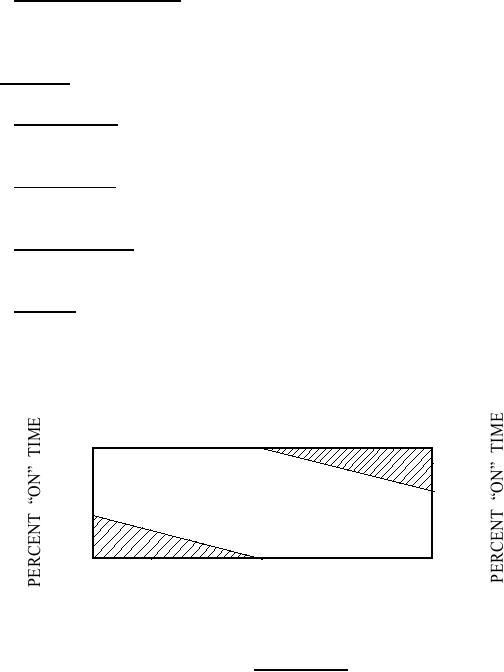

3.4.4 Flashing. The "flashing rate" and the "percent on time" of normally closed type

flashers shall be within the unshaded area of the polygon in figure 1.

60

90

120

75

75

60

40

30

30

90

60

120

FLASHING RATE (FLASHES PER MINUTE)

Figure 1. Flashing rate.

"Flashing rate" and "percent on time" shall be measured after the flasher has been operating for

five consecutive cycles and shall be an average of at least three consecutive cycles. The

"flashing rate", as defined in 6.4.4, shall be not less than 60 and not more than 120 flashes per

minute. The average "percent on time", as defined in 6.4.5, shall be as indicated in the polygon

above. When the control lever or hazard warning switch is returned to neutral position, the "turn

off time", as defined in 6.4.7, shall be less than 1.0 second (see 4.4.3.1).

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business