MIL-DTL-62069G(AT)

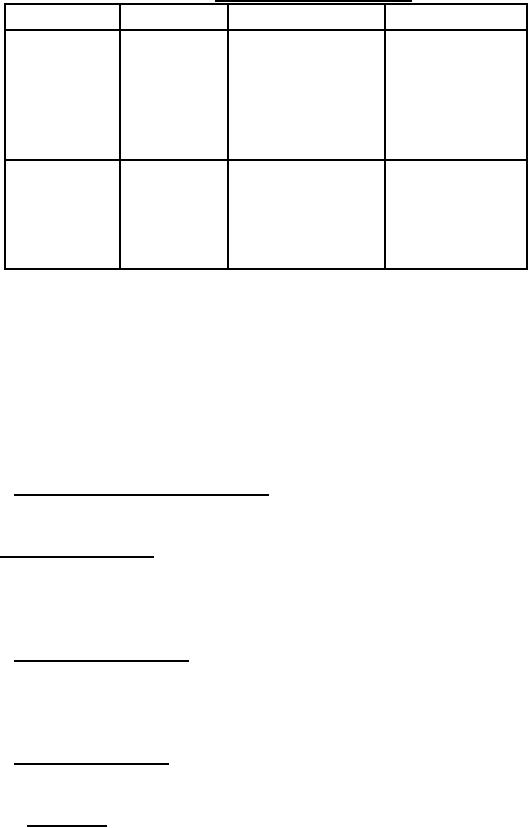

TABLE IV. Order of conformance tests.

Sample

Paragraph

Tests

4.4.4.1

Actuation

(See Note 1)

Flasher

4.4.3.1

Flashing

(See Note 2)

4.4.3.2.2

Overload

(See Note 3)

4.4.3.1

Flashing

(See Note 2)

4.4.3.3

Reverse Polarity

(See Note 4)

4.4.3.1

Flashing

(See Note 2)

Control Unit 4.4.4.1

Actuation

(See Note 1)

4.4.3.1

Flashing

(See Note 2)

4.4.5.5

Waterproofness

(See Note 5)

4.4.3.1

Flashing

(See Note 2)

4.4.4.1

Actuation

(See Note 1)

NOTE 1: Perform in accordance with 4.5.3.1 but actuate twice.

NOTE 2: Check each unit to 18, 24 and 30 volts. Eliminate "Average flashing

rate" and "percent on time" specified in 3.4.4.

NOTE 3: Short for approximately 15 seconds.

NOTE 4: Apply reverse polarity only once.

NOTE 5: Submerge in tap water one minute. Electrical operation not required.

A continuous stream of bubbles from the unit shall be cause for

failure.

4.3.4 Conformance tests for control units. All (100%) control units shall be subjected to

the tests specified in table IV.

4.4 Verification methods. The types of verification methods included in this section are

visual inspection, measurement, sample tests, full-scale demonstration tests, simulation,

modeling, engineering evaluation, component properties analysis, and similarity to previously-

approved or previously-qualified designs.

4.4.1 Verification alternatives. The manufacturer may propose alternative test methods,

techniques, or equipment, including the application of statistical process control, tool control, or

cost-effective sampling procedures, to verify performance. See the contract for alternatives that

replace verifications required by the specification (see 6.2).

4.4.2 Inspection conditions. Unless otherwise specified (see 6.2), all inspections shall be

performed in accordance with the test conditions specified below (see 4.4.2.1).

4.4.2.1 Conditions. Tests shall be conducted under general laboratory conditions

acceptable to the Government. Unless otherwise specified herein, all tests shall be conducted at

ambient room air temperature. The ambient room temperature shall be maintained at 77±15F.

Unless otherwise specified herein, or in applicable specifications, test specimens shall be

thermally stabilized for one hour prior to being subjected to tests.

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business