MIL-DTL-62366D(AT)

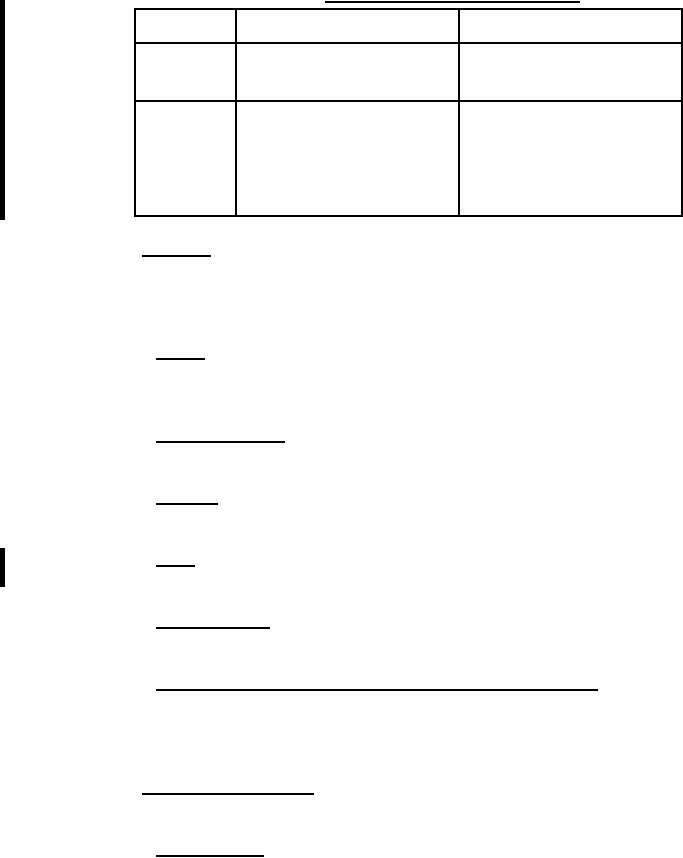

TABLE III. Class II hook up wire requirements.

Connector

Pin

Wire type and size

J1

A, D

2 - # 6 Braided

B, C, E, F

SAE-AS81044/6-8-9

J2

A through F, J through M, P,

NEMA-WC27500-20ML2T08

R through Z, a, b, c, e, f, g, h

H

NEMA-WC27500-20ML1T08

G, N, W, d, j

Shield return

3.3 Materials. Materials used shall be in accordance with applicable drawings (see 3.2

and 3.3.1 through 3.3.6). When not thereby designated, the materials shall be in accordance with

the manufacturer s materials specifications for slip ring assemblies and shall meet all of the

operating and environmental requirements as specified herein (see 4.3.4).

3.3.1 Metals. All metals used in the slip ring assembly shall be of corrosion resistant

type or shall be suitably protected to resist corrosion during the life of the assembly. The use of

dissimilar metals shall be avoided, unless suitably treated to resist galvanic corrosion (see 4.3.4).

3.3.2 Fungus resistance. All slip ring assembly materials shall be fungus non-nutrients

(see 4.3.4.1.).

3.3.3 Castings. If castings are used, the casting material, type, and quality shall be as

specified in the contract or order (see 4.3.4 and 6.2).

3.3.4 Seals. Seals shall be made of material compatible with MIL-PRF-6083,

MIL-PRF-46170, or commercial equivalents, and water (see 4.3.4).

3.3.5 Sealed bearings. Bearings shall be thoroughly cleaned and then filled at least

80 percent (%) with grease conforming to MIL-PRF-23827, or equivalent (see 4.3.4).

3.3.6 Recycled, recovered, or environmentally preferable materials. Recycled,

recovered, or environmentally preferable materials should be used to the maximum extent

possible provided that the material meets or exceeds the operational and maintenance

requirements, and promotes economically advantageous life cycle costs.

3.4 Operating requirements. Slip ring assemblies shall meet the operational

requirements as specified in 3.4.1 through 3.4.8 (see 4.3.5).

3.4.1 Starting torque. The torque required to initiate motion of the rotor assembly shall

not exceed 62.5 pound-force inch (lbf-in) (7.1 Newton-meters (N-m)) (see 4.3.5.1).

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business