MIL-DTL-62366D(AT)

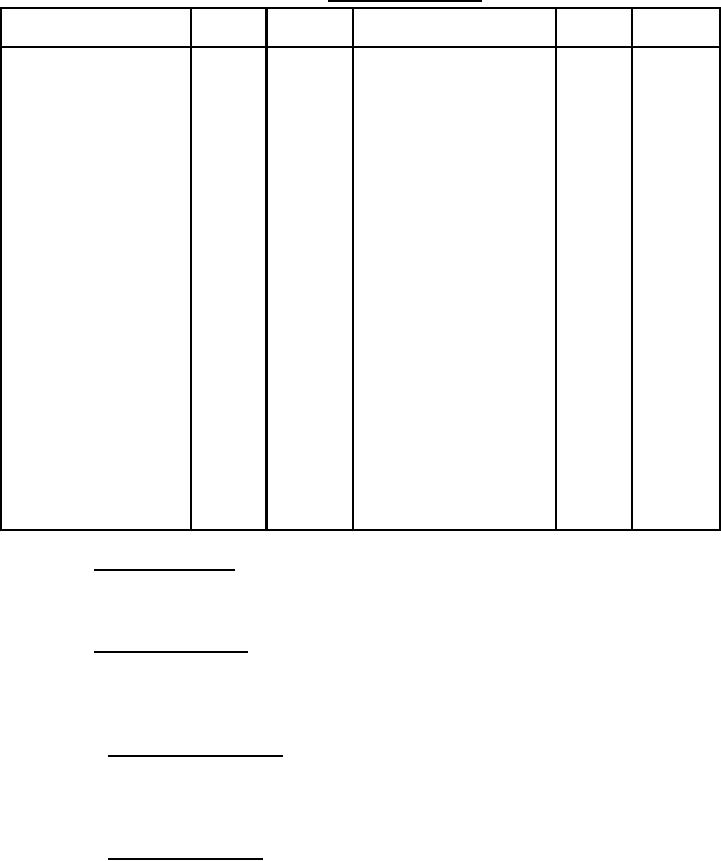

TABLE VI. Verification methods.

Require-

Verifica-

Require-

Verifica-

Title

Title

ments

tion

ments

tion

3.2

4.3.3

Capacitance

3.4.6.2.1

4.3.5.5.2.2

Design and construction

Housing and mounting

3.2.1

4.3.3.1

Noise

3.4.6.2.2

4.3.5.5.2.3

base assembly

Dielectric withstanding

3.4.6.3.1

4.3.5.5.3.1

Brush block and terminal

3.2.2

4.3.3

voltage

assembly

Resistance

3.4.6.3.3

4.3.5.5.3.3

Rotor assembly

3.2.3

4.3.3

Electromagnetic coupling

3.4.7

4.3.5.6

Interface requirements

3.2.4

4.3.3.2

Sheathed leads

3.4.8

4.3.5.7

3.3

4.3.4

3.5

4.3.7

Materials

Support and ownership

Metals

3.3.1

4.3.4

requirements

Fungus resistance

3.3.2

4.3.4.1

Flammability

3.5.1.1

4.3.7.1

Castings

3.3.3

4.3.4

Hazardous materials

3.5.1.2

4.3.7.1

Seals

3.3.4

4.3.4

Finish

3.5.2

4.3.7.2

Sealed bearings

3.3.5

4.3.4

Identification marking

3.5.3

4.3.7.3

3.4

4.3.5

3.6

4.3.8

Operating requirements

Operating environment

Starting torque

3.4.1

4.3.5.1

requirements

Normal speed

3.4.2

4.3.5.2

Water immersion

3.6.1

4.3.8.1 &

Maximum speed

3.4.3

4.3.5.3

4.3.8.1.1

Stopping

3.4.4

4.3.5.2

Atmospheric pressure

3.6.2

4.3.8.2

Static limit load capacity

3.4.5

4.3.5.4

Sand and dust

3.6.3

4.3.8.3

Power rings

3.4.6.1

Shock

3.6.4

4.3.8.4

4.3.5.5.1

&

4.3.5.5.1.1

Vibration

3.6.5

4.3.8.5

Control rings

3.4.6.2

High temperature

3.6.6

4.3.8.6

4.3.5.5.2

&

4.3.5.5.2.1

Low temperature

3.6.7

4.3.8.7

4.2 Order of inspection. The inspection sequence may be in any order except that the

housing and mounting base assembly test (see 4.3.3.1) and the operating environment

requirements verifications (see 4.3.8) shall precede all other tests.

4.3 Verification methods. The types of verification methods included in this section are

visual inspection, measurement, sample tests, full-scale demonstration tests, simulation,

modeling, engineering evaluation, component properties analysis, and similarity to previously

approved or previous qualified designs.

4.3.1 Verification alternatives. The manufacturer may propose alternative test methods,

techniques, or equipment, including the application of statistical process control, tool control, or

cost effective sampling procedures, to verify performance. See the contract for alternatives that

replace verification required by this specification (see 6.2).

4.3.2 Inspection conditions. Unless otherwise specified (see 6.2), inspection conditions

shall be as follows:

a. Ambient air temperature: 75±10 °F (24±5.5 °C)

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business