MIL-DTL-53078A

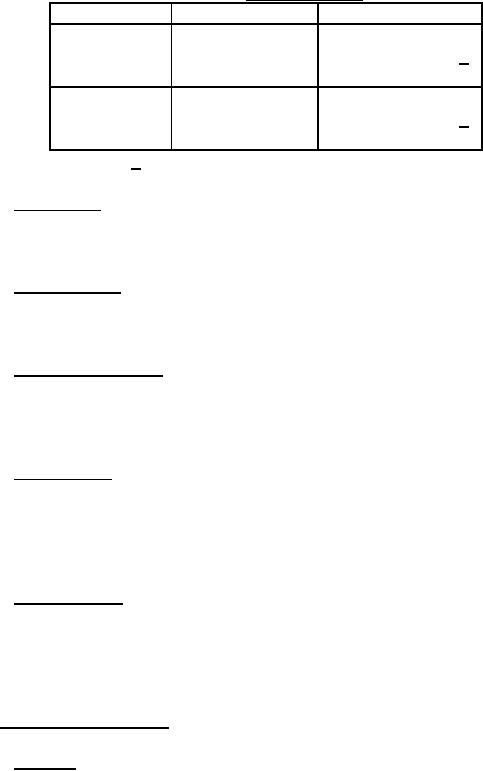

TABLE I. Vibration levels.

Axis

Frequency (Hz)

Amplitude

Verticle

5 to 25

±1.0 g

25 to 57

0.03 inch D.A. 1/

44 to 500

±5.0 g

Longitudinal

5 to 25

±1.0 g

And

25 to 57

0.03 inch D.A. 1/

Longitudinal

44 to 500

±3.0 g

NOTE: 1/ Double amplitude (D.A.)

3.6.3 Basic shock. The CLAMS mounting kit shall meet the requirements of 3.4 during

and after exposure to shock impulses of 30 ±3 g, 11 ±1.1 milliseconds (ms) half sine wave

applied in each direction of the three mutually perpendicular axes (see 4.5.10).

3.6.4 Ballistic shock. The mounting kit shall meet the requirements of 3.4 during and

after exposure to shock impulses of 200 ±20 g, 0.5 ±0.1 ms half sine wave applied in each

direction of the three mutually perpendicular axes (see 4.5.11).

3.6.5 High intensity shock. The converter box and parts thereof, shall remain intact and

shall not become secondary projectiles when subjected to high intensity shock levels of

980 ±98 g, 0.5 ±0.1 ms at the assembly s mounting interface. This shall include the impulses in

each direction of the three mutually perpendicular axes (see 4.5.12).

3.6.6 Submergence. There shall be no evidence of air leakage when the converter box is

pressurized with air to 6.0 ±0.5 psig and completely submerged in water to a depth of 6 inches

minimum measured from top surface. Electrical connectors shall be capped during

submergence. The CLAMS converter box shall meet the requirements of 3.4 after submergence

(see 4.5.13).

3.6.7 Cleaning spray. The converter box shall not be damaged by and shall meet the

performance requirements of 3.4 after exposure to a jet spray of tap water applied perpendicular

to and at a distance of one (+1.0, -0.0) foot from the component surface at a cleaning rate of 1.0

square foot per minute for a period of 10 minutes minimum. The water jet shall be derived from

nozzle having a orifice diameter of 0.25 inch and a nozzle pressure of 25 psig (see 4.5.14).

3.7 Treatment and painting.

3.7.1 External. The portions of the mounting kit, not including the deflector, normally

painted shall be cleaned, treated, and painted in accordance with Drawing 12344344 color 383

green. The deflector shall be cleaned per applicable method of specification TT-C-490 and

painted with MIL-P-14105 color black.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business