MIL-DTL-46725D(AT)

3.2.1 Construction. The valve shall be constructed to the form and dimensions shown on

the applicable drawing listed in table I. The shape is optional within the maximum dimensions.

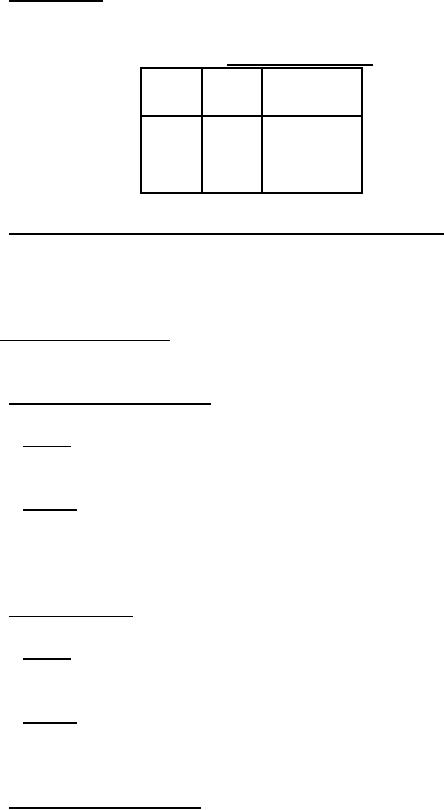

TABLE I. Applicable drawings.

Valve Valve

Drawing

Type Class

Number

I

-

9093264

II

A

9098279

B

9094352

3.2.2 Recycled, recovered, or environmentally preferable materials. Recycled, recovered,

or environmentally preferable materials should be used to the maximum extent possible provided

that the material meets or exceeds the operational and maintenance requirements, and promotes

economically advantageous life cycle costs.

3.3 Operating requirements. Each valve shall provide the following functional,

operational, and performance capabilities.

3.3.1 Flow rate and pressure drop.

3.3.1.1 Type I. The flow rate shall be 7.6 L/min (2 gal/min) through any interconnected

ports with no more than 1034 kPa (150 psi) pressure drop across the valve.

3.3.1.2 Type II. The flow rate of class A valves shall be 7.6 L/min (2 gal/min) through

any interconnected ports, with less than 689 kPa (100 psi) pressure drop across the valve. The

flow rate of class B valves shall be 22.7 L/min (6 gal/min) with less than 1724 kPa (250 psi)

pressure drop across the valve.

3.3.2 Operating torque.

3.3.2.1 Type I. The maximum operating torque shall be 5.6 Newton-meters (N-m)

[50 pound-inches (lb-in.)] with 20 684 kPa (3000 psi) applied at the pressure port.

3.3.2.2 Type II. The maximum operating torque shall be 2.8 N-m (25 lb-in.) for class A

valves, and 5.9 N-m (52 lb-in.) for class B valves, with 20 684 kPa (3000 psi) hydraulic pressure

applied at the pressure port.

3.3.3 Normal operating pressure. The valve shall operate satisfactorily throughout a

hydraulic pressure range of 0 to 20 684 kPa (3000 psi) applied to any port, except the return port,

while using hydraulic fluid conforming to MIL-PRF-6083.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business