MIL-PRF-46720C

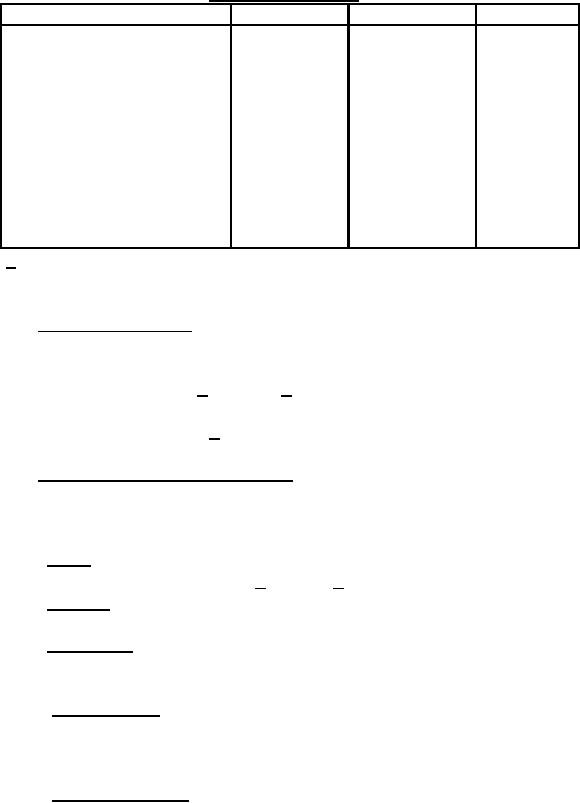

TABLE I. Verification methods - Continued.

Title

Requirements

Verification

Sample No.

Vibration

3.6.7

4.3.6.7

Operating pressure

3.3.2

4.3.3.2

Rated flow and pressure drop

3.3.5

4.3.3.4

Proof pressure

3.3.6

4.3.3.5

Humidity

3.6.8

4.3.6.8

Rated flow and pressure drop

3.3.5

4.3.3.4

4

Proof pressure

3.3.6

4.3.3.5

Salt spray

3.6.4

4.3.6.4

Operating pressure

3.3.2

4.3.3.2

Rated flow and pressure drop

3.3.5

4.3.3.4

Proof pressure

3.3.6

4.3.3.5

1/ Each even numbered sample shall receive one environmental test, sequentially

in the order listed in 4.3.6.

4.3.2 Inspection conditions. Unless otherwise specified (see 6.2), all inspections shall be

conducted under the following conditions:

a. Air temperature: 77 + 15°F (30 + 8°C).

b. Barometric pressure: 28.5 + 2 inches of mercury (Hg) (96 + 7 kPa).

c. Relative humidity: 50 + 30 percent (%).

4.3.3 Operating requirements verification. Complete each verification under paragraph

4.3.3. Unless otherwise specified (see 6.2), performance testing shall be conducted under the

following conditions:

a. Fluids. All tests shall be performed with hydraulic fluid (see 6.3). The hydraulic

fluid temperature shall be 90 +20°F (32 + 11°C).

b. Cleaning. All grease or foreign material shall be removed from interior parts of the

valve before testing.

c. Air removal. Air shall be completely removed from all hydraulic portions of the

valves prior to tests.

4.3.3.1 Operating time. To determine conformance to 3.3.1, the valve shall be mounted

and electrically connected as in intended use, with 18 Vdc applied. The valve shall be operated

(change port interconnection), and the time required recorded.

4.3.3.2 Operating pressure. To determine conformance to 3.3.2, the valve shall pass the

tests of 4.3.3.2.1 through 4.3.3.2.3, as applicable.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business