MIL-DTL-46735C(AT)

4.3 Conformance inspection. Conformance inspection shall include the examinations of

4.4 (see table III) and the tests of 4.5.3.1 (see table IV).

4.3.1 Sampling. Sampling for conformance inspection shall be selected in accordance

with ANSI/ASQC Z1.4.

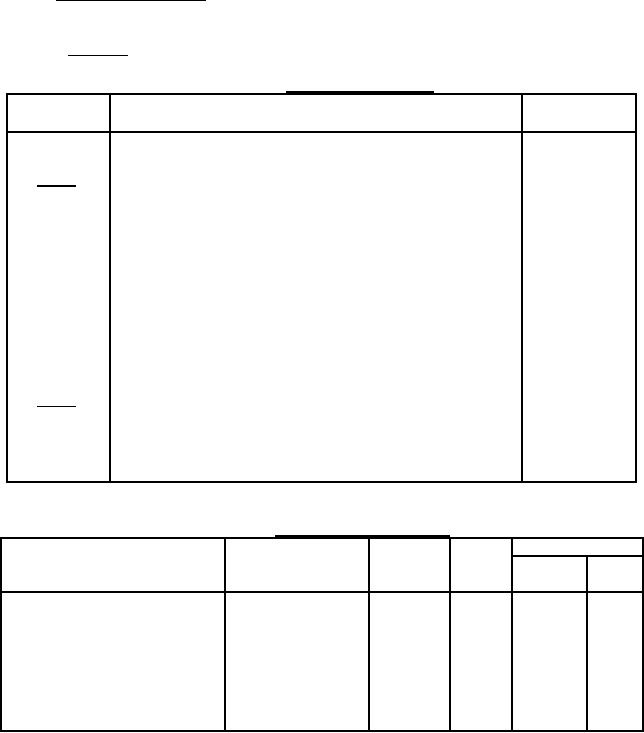

TABLE III. Classification of defects

.

Method of

Category

Defect

examination

Critical

None

Major:

101

Winch line size capabilities (see 3.3).

Visual

102

Improper, poor assembly practice (see 3.3).

Visual

103

Dimension affecting interchangeability (see 3.3).

SIE 1/

104

Missing or inoperative components (see 3.3 and 3.3.3).

Visual and

functional

105

Inferior quality (see 3.3).

Visual

106

Winch spooling malfunction (see 3.3.1 and 3.3.2).

Visual and

functional

107

Adjustment and controls interference, rough operation,

Functional

no response (see 3.3.1 and 3.4.4).

Minor:

201

Incorrect type of lubrication (see 3.3).

Visual

202

Improper preparation for painting, color, application

Visual

(see 3.5).

203

Incorrect or missing markings (see 3.6).

Visual

1/ SIE = Standard Inspection Equipment.

TABLE IV. Classification of inspections.

Conformance

Inspec-tion

First

Examin-

Title

Requirement

article

ation

Tests

Materials and construction

3.2

4.5.1

X

Defects

3.3, 3.3.1, 3.3.2,

4.5.2

X

X

3.3.3, 3.5, and 3.6

Functional reliability

3.4.1

4.5.3.1

X

X

Environmental

3.4.1

4.5.3.2

X

Winch speed and line pull

3.4.2

4.5.3.1

X

X

Brake

3.4.3

4.5.3.1

X

X

Controls

3.4.4

4.5.3.1

X

X

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business