MIL-B-45390A(AT)

4.5 Quality conformance inspection.

4.5.1 Sampling.

4.5.1.1 Lot formation. An inspection lot shall consist of all the bulldozer kits of one type

and part number, from an identifiable production period, from one manufacturer, submitted at

one time for acceptance.

4.5.1.2 Sampling for examination. Samples for quality conformance examination shall be

selected in accordance with general inspection level II of MIL-STD-105. Before sampling may

be initiated, the contractor shall establish by examination of at least 3 consecutively produced

bulldozer kits that the process average percent defective, as defined in MIL-STD-105, is not

greater than the specified AQLs.

4.5.2 Examination.

4.5.2.1 Acceptable quality level. Each sample selected in accordance with 4.5.1.2 shall be

examined to determine conformance to the following acceptable quality levels (AQLs).

Classification

AQL

Major

25/100

Minor

150/100

4.5.2.2 Classification of defects. For examination purposes, defects shall be classified as

listed in table III.

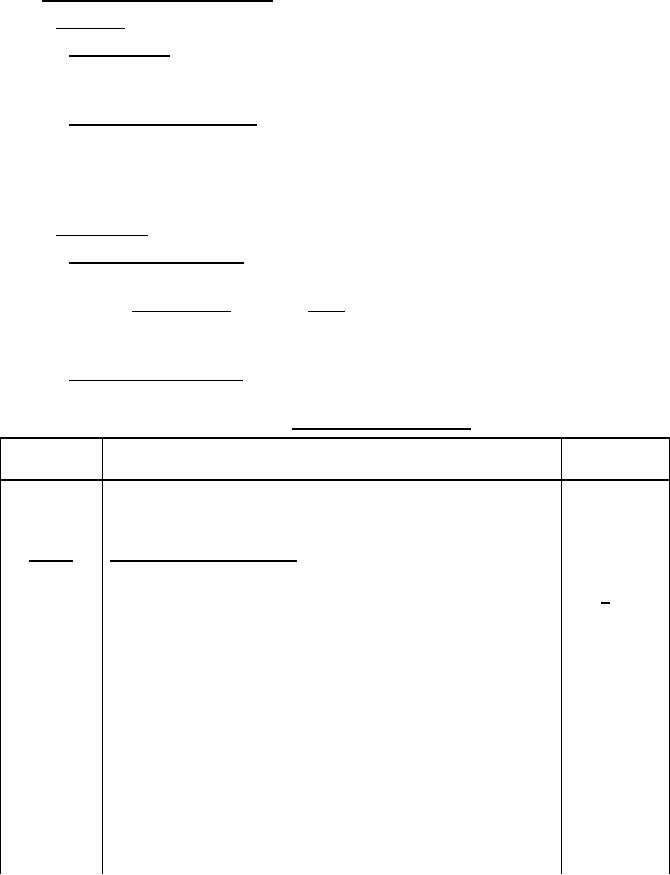

TABLE III. Classification of defects.

Method of

Category

Defect

examination

Critical

None

Major

AQL 25 defects/100 units

101

Assembly, incomplete (see 3.3).

Visual

102

Dimensions affecting interchangeability, not within tolerance

SIE 1/

(see 3.3).

103

Right angle drive, pump, and coupling; improper assembly.

Visual

104

Front mounting brackets and moldboard; improper weld or

Visual

improper assembly.

105

Headlamps and guards; improper assembly, inoperative or

Visual and

damaged.

Functional

106

Control assembly and guards; improper assembly, damaged,

Visual and

malfunction, or improper weld.

Functional

107

Installation fixture and templates; damaged or missing.

Visual and

Functional

108

Hydraulic cylinders, reservoir, filter, hoses, pipes, and

Visual and

guards; improper assembly, malfunction, leaks or improper

Functional

weld.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business