MIL-B-45390A(AT)

3.4.1 Hydraulic operating system. The hydraulic system shall be powered by a hydraulic

pump driven through a right angle drive speed reducer attachable to the transmission power

take-off shaft. A four-position control valve shall direct the oil flow to the double-acting

hydraulic cylinders for control of the blade. The pump when operating at 2800 revolutions per

minute (rpm) shall deliver a minimum flow of 60 gallons per minute at a pressure of

1000 pounds per square inch (psi) (see 4.6.3.1).

3.4.2 Controls and linkage. Prior to initial bulldozing operation, all controls and linkage

shall be operated through all ranges of operation (see 4.6.3.2).

3.4.3 Safety relief valve. Hydraulic system shall be protected from high shock pressures by

a relief valve set to operate at 5000 psi (see 4.6.3.3).

3.4.4 Digging depth. Full downward pressure applied to piston shall hold the cutting edge of

the blade down to not less than 9 inches below ground level. The hydraulic system shall hold the

moldboard at any height within operating range, or allow moldboard to float at ground level

(see 4.6.3.4).

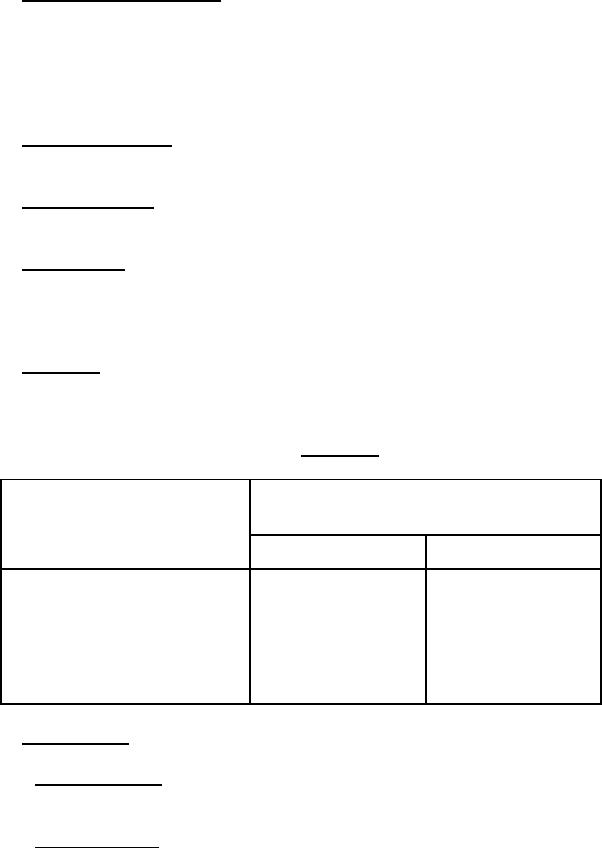

3.4.5 Rate of lift. The hydraulic system shall lift and lower the moldboard at rates of speed

listed in table I. The specified rates of speed shall be accomplished when using oil specified in

3.3.1 with an applied pressure of 1000 psi (see 4.6.3.5).

TABLE I. Rate of lift.

Engine speed

Minimum rate of lift or lower

(rpm)

(inches per second)

minimum

Up

Down

1000

2.5

6.5

1500

4

6.5

2000

5

6.5

2400

5.5

6.5

2800

6

6.5

3.4.6 Environmental.

3.4.6.1 High temperature. The bulldozer shall meet the requirements of 3.4.1 through 3.4.5

during and after exposure to temperatures up to 115oF (see 4.6.1.6.1).

3.4.6.2 Low temperature. The bulldozer shall meet the requirements of 3.4.1 through 3.4.5

during and after exposure to temperatures down to -40°F (see 4.6.3.6.2).

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business